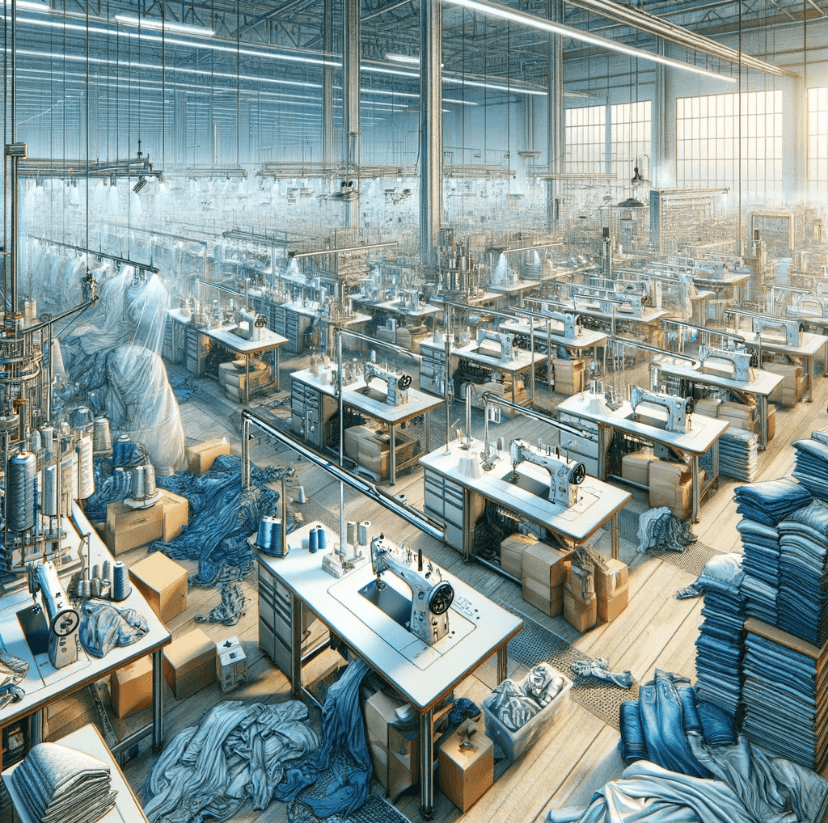

"Deep Crisis in the Textile Industry: Unemployment and Costs Are Climbing!"

150 thousand people were laid off in the EXTRACT sector in the last year. Unions say, "The employment of approximately 1.5 million workers is in danger." Increasing costs, expensive production, unpredictable exchange rates, loss of purchasing power, and unavailable stocks dealt a blow to the sector.

Increasing costs, production becoming more expensive compared to rival countries, unpredictable exchange rates, a decrease in demand due to the decline in purchasing power, and full stocks have hit textiles and ready-made clothing, which are important sectors of export, as well as many other sectors. Many textile factories are trying to get over the slow season by providing annual leave to workers. While unions say, "The employment of approximately 1.5 million workers is in danger," employers say, "The sector is in transformation and this will last at least a year." “Cheap financing is essential to survive in this process,” he says.

Stating that they shrank by 10 percent on a turnover basis and 15 percent on a quantity basis in the first six months of this year, Ramazan Kaya, President of the Turkish Clothing Manufacturers Association, stated that in parallel with this, there was a decrease of approximately 150 thousand in employment in the last year. Stating that there are many reasons for the contraction in the sector, Kaya stated that the main reason for the problem is the decrease in demand due to the recession in Europe.

Kaya said: “Last year's stocks did not melt away, and when fast fashion turned into slow fashion, our purchasing groups were no longer in a hurry. When the price increased due to cost, they quoted prices from countries such as Bangladesh and India. The price difference between us and these countries, which was 15 percent, is now 50 percent. Our labor fee is 250-300 dollars for service, food, nursery, etc. When calculated, it came to 700 dollars.”

Explaining that the sector has entered a transformation process for value-added production and that this may last a year, Kaya said, "We need low-cost and long-term financing to survive."

Employment is at risk

Mustafa Gültepe, President of the Istanbul Ready-made Clothing and Apparel Exporters' Association, stated that capacity utilization rates in textiles decreased to 70 percent and gave the following information: "The reason for the work stoppage is 70-80 percent due to our loss of competitiveness and 20-25 percent due to the decrease in demand." Not only in Europe but also in the domestic market, our brands also turned to imports instead of the domestic market when the exchange rate did not increase as much as inflation. "Factories are trying to overcome this stagnant period by providing annual leave to workers."

Gürkan Gözmen, member of the Board of Directors of the Istanbul Leather and Leather Products Exporters Association, stated that the problems in the leather industry are even greater and said, “The Russia-Ukraine war affected our industry. "Since hotels are expensive, the number of tourists and our sales to tourists have also decreased," he said.

Textile Workers Union General Secretary Celal Aslan also stated that the use of compulsory annual leave in the sector has increased and said: “Most factories close on Thursday and Friday and work half-time. The decline in exports hit the sector. "There are approximately 1.5 million employees in this sector and employment is in great danger right now," he said.

Süleyman Sönmez, President of the Turkish Enterprise and Business Confederation (TÜRKONFED), was in Aydın within the scope of the meetings held with the theme of "Turkey in Our Dream". Stating that Turkey should exit the minimum wage economy in his speech here, Sönmez said, "We have to initiate the transformation from a minimum wage economy, which is the product of a low and medium-intensity production structure, to a high technology and high value-added production economy." Sönmez also pointed out the necessity of reducing budget expenditures and implementing savings policies that will set an example for the society, instead of increasing the tax burden.

586 companies closed, 150 thousand people became unemployed

While high inflation and the increase in the exchange rate increased the costs of companies, the economic crisis deepened further when the government's exorbitant increases in taxes and fees were added to these. Due to the increase in costs and decrease in demand in the textile industry, 586 companies were closed and 150 thousand employees became unemployed. Companies that are still operating are resisting the huge costs.

The textile industry is sounding the alarm in Turkey, where the economic crisis is getting deeper. While some companies declare bankruptcy in the face of rising costs and falling demand, companies that remain open are also resisting the crisis.

Sharp decline in new orders

According to Yener Karadeniz's report from Ekonomim, the indicators for the coming period are not very bright. According to Istanbul Chamber of Industry PMI data for July, the textile sector stood out as the sector with the sharpest slowdown in new orders among the 10 sectors monitored with a PMI of 49.9.

While new orders lost momentum for the second month in a row, the slowdown in July was at the highest rate since October last year. As a result of the slowdown in new orders, the first decline in production in the last 5 months was recorded, while employment and purchasing activities also weakened. On the other hand, according to the Central Bank data, the capacity utilization rate in the sector decreased to 70.4 percent. So how did the sector, which has broken consecutive production and export records in recent years and made the largest investments in its history, come to this situation? Because, according to the Investment Incentive Statistics of the Ministry of Commerce, the sector had planned new investments of 22.4 billion TL and more than 13 thousand new employment in 2021 alone. According to Ahmet Öksüz, President of Istanbul Textile and Raw Materials Exporters Association (İTHİB), the main reasons for this situation are earthquake, falling demand in the national and international arena and increasing imports. Pointing out that the disruption of one of the chain mechanisms that support production in the sector with an annual production value of 49 billion dollars has a negative impact on the entire sector, Öksüz said, “The decrease in capacity utilization rates continues due to increasing imports. Dumped products, which come at prices even lower than the manufacturer's cost, unfortunately cause the textile industry to be in a difficult situation. In fact, many production facilities in an important textile city like Kahramanmaraş unfortunately decided to stop production. Our sector tries to keep prices with labor costs on the one hand and energy costs on the other; It cannot fight against unfair competition in imports. Because this is an issue that needs to be tackled collectively with private sector-public cooperation. "In this context, we are constantly working in coordination with our Ministry of Commerce against the unfair import increase," he said.

The economic crisis also hit the textile and clothing industry... Factories are moving abroad

The migration of textile and clothing factories abroad has begun. Rafi Ay, Chairman of Öz İplik-İş Union, said that brands are moving their factories abroad due to the economic crisis and signaled that a new unemployment crisis may arise.

The economic crisis, which has manifested itself seriously in the last year, also hit the textile and clothing sectors. Rafi Ay, Chairman of Öz İplik-İş Union, said that the economic crisis hit their own sectors and employees, and famous brands moved their factories abroad. Ay stated that in the last year, factories producing many famous brands in the textile and clothing industry went to countries such as Egypt, Algeria, Tunisia and Bangladesh, 604 small businesses were closed and 134 thousand workers lost their jobs.

Calling on the economic management to develop new solutions and policies that will keep the sector afloat, Ay warned that otherwise there could be huge losses in the sector, which has 20 billion dollars of exports and 1.5 million jobs.